At Cleanrooms USA, we're focused on offering slicing-edge cleanroom environments that satisfy the stringent requirements of industries starting from pharmaceuticals and biotechnology to electronics and aerospace.

Ordinarily Utilized in manufacturing or scientific analysis, a cleanroom is usually a controlled environment that features a lower standard of pollutants for example dust, airborne microbes, aerosol particles, and chemical vapors. For being actual, a cleanroom contains a managed degree of contamination that's specified by the amount of particles per cubic meter at a specified particle sizing.

Dense freight, with its decreased probability of harm, contrasts with handling fragile things like glass in comparison with far more sturdy elements like bricks.

The objective of this state is to ascertain a baseline for cleanliness, supplying insights into your inherent purity with the setting with no impact of human things to do or tools Procedure.

grade N suggests that the scholar's performance fell in need of the normal needed for grade E (e) by a slender margin.

Parenteral drug formations also allow for for higher dosage concentrations in situation when important therapies ought to enter the blood stream instantly, which include crisis surgery, heart attacks or infections, and so on.

It’s essential to keep in mind that the shown greatest particle counts Establish on one another. This means that one 6-micrometer particle counts towards the limit for particles around five micrometers, in addition to for many of the reduced sizing limits.

For Grade D, the airborne particle classification is the equivalent of the ISO 8 cleanroom at relaxation. Even though in Procedure, the particle classification isn't predefined; it'll count on the character with the procedures happening inside the zone. This can click here be what we connect with a Thoroughly clean Non-Classified (CNC) area.

The airflow method of a class 100 cleanroom is maintained at optimistic force that is bigger than the air force outdoors the cleanroom, which forces the air inside the cleanroom to flow exterior. This method prevents contaminated particulate make any difference from moving into the cleanroom.

An environmental chamber is undoubtedly an enclosure used to examination the consequences of several different problems on a product, part, section, or assembly. These hugely technical items of kit are capable of simulating the types of disorders more info a product could face while in use...

For several blend device–drug developers, pointers and applicable production standards have and are evolving swiftly. These a solid advancement Within this sector in the pharma sector has elevated important necessities on enhancement, formulation, scientific offer, design transfer and control, danger management, and commercial source of those mix solutions, building equally their engineering and compliance quite difficult.

503A addresses compounding by condition or federally certified facility by certified staff (pharmacist/ physicians)

Whilst the Non-Viable Particle Counting is the 1 that can decide how clear your cleanroom is, all 4 exams Supply you with precious facts to your classification and basic cleanroom maintenance. The checks are:

Lessened downtime: Modular cleanroom set up will cause considerably fewer disruption to day by day functions, letting many end users to help keep some or all operations running without disruption.

Tatyana Ali Then & Now!

Tatyana Ali Then & Now! Jenna Jameson Then & Now!

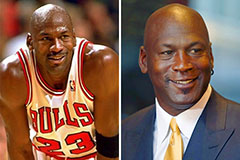

Jenna Jameson Then & Now! Michael Jordan Then & Now!

Michael Jordan Then & Now! Tina Majorino Then & Now!

Tina Majorino Then & Now! Kerri Strug Then & Now!

Kerri Strug Then & Now!